Proper Surface To Install Aluminum Siding

Aluminum fascia goes directly over the wood fascia and has a lip at the bottom that laps over the outer edge of the installed aluminum soffit.

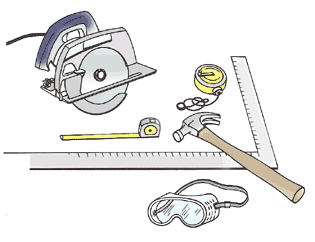

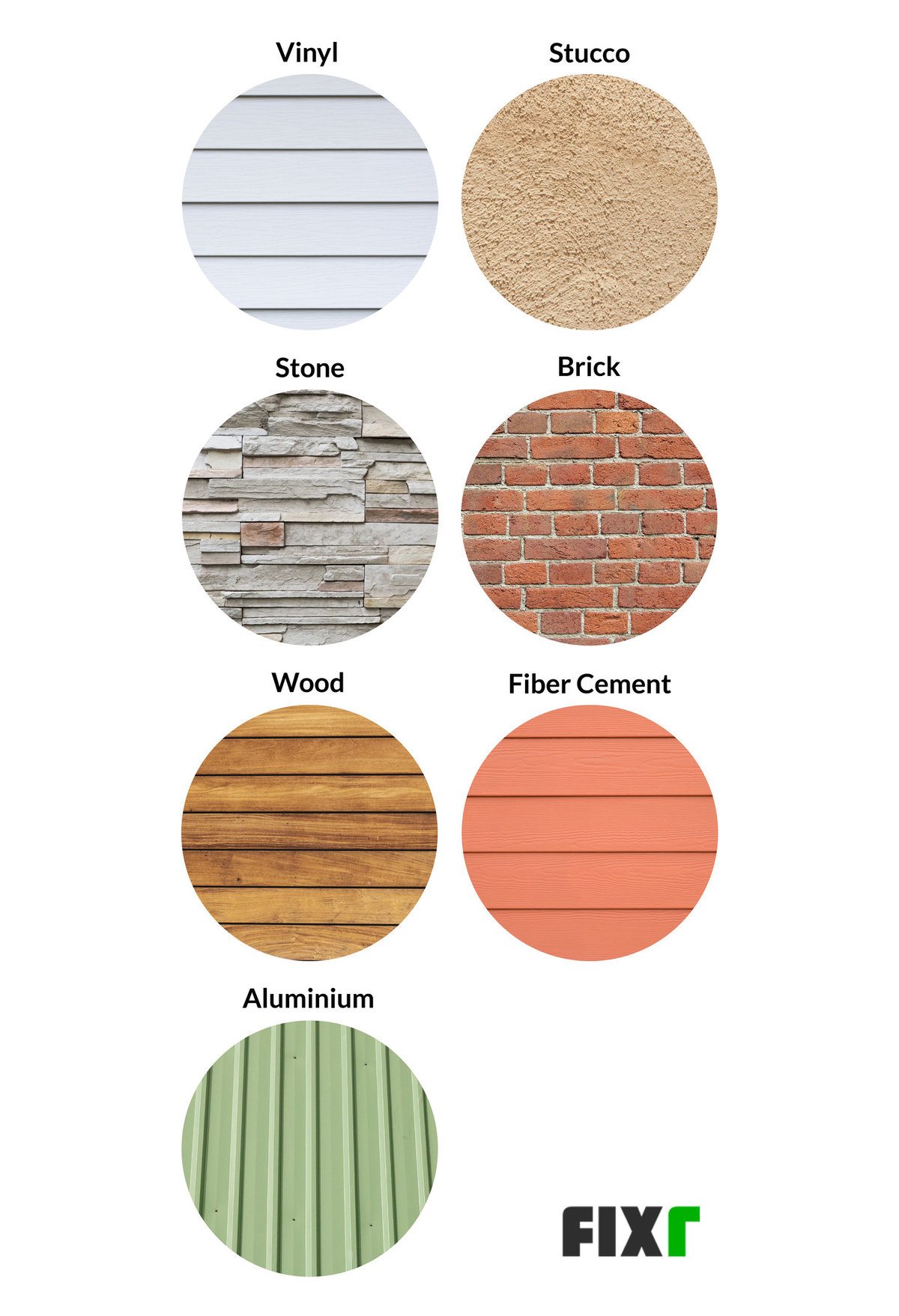

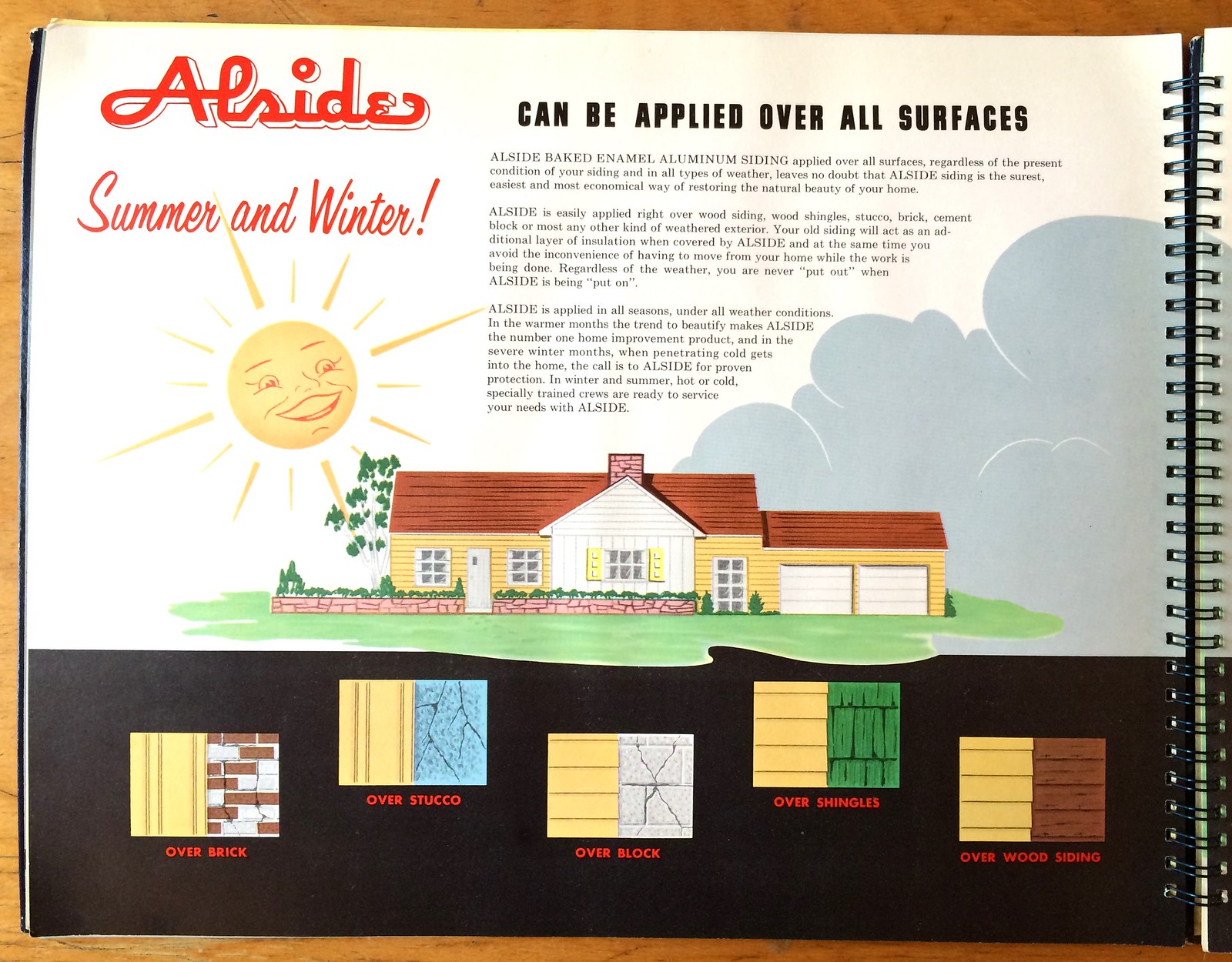

Proper surface to install aluminum siding. A vinyl siding system consists of various trim pieces such as j channels corner posts and other trim pieces. Things you ll need furring strips and sheathing if you re working on an uneven surface hammer nails metal siding j channel tin snips or power saw measuring tape level. How to install individual aluminum siding corners of hardie plank siding. Applying weather resistant sheathing over old siding is the fastest easiest way to provide a flat nailable surface for vinyl or aluminum siding installation.

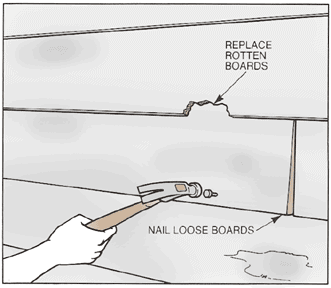

The following is the proper procedure for a roof repair company. Nail screw head diameter must be 3 8 to 7 16 with a maximum shank diamater of 160. It comes in two standard widths. Be sure door and window frames can be built out relatively easily before taking this approach.

Proper installation of step flashing. The surface to which the panels attach must be smooth so that they lie flat. Always use aluminum 1 1 2 inch 3 81 cm roofing nails to install aluminum siding. Step flashings are to be installed one per course.

For aluminum and vinyl 3 8 inch foam board insulation is a reliable backing choice. 6 and 8 in. Use a piece of painted aluminum sheet 150 mm 6 wide and adjusted to proper length. Measure the width of your wood fascia to determine which width to buy.

The roof deck flange of step flashings are to be fastened to the surface of each shingle in a position whereby the next course of shingles will cover up hide the flashing from view. On each side of the corner now shaped measure a distance equal to the width of the mouldings. The tricky part can be dealing with the added thickness where siding meets windows and doors. If you use a portable folding brake insert a strip of aluminum sheet painted side down and fold along centre at a 90 angle.