Process Control For Sheet Metal Stamping

Stamping also known as pressing is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

Process control for sheet metal stamping. These designs are then translated into stamping dies by skilled craftsmen known as diemakers. Sheet metal forming is a complex process and most often characterized by partial differential equations that are numerically solved using finite element techniques. Once these stamping dies are mounted into presses sheet metal is fed to them. Stamping process capability and implications for design die tryout and process control updates ongoing research activities by the body systems analysis team and the manufacturing systems staff at the university of michigan s office for the study of automotive transportation.

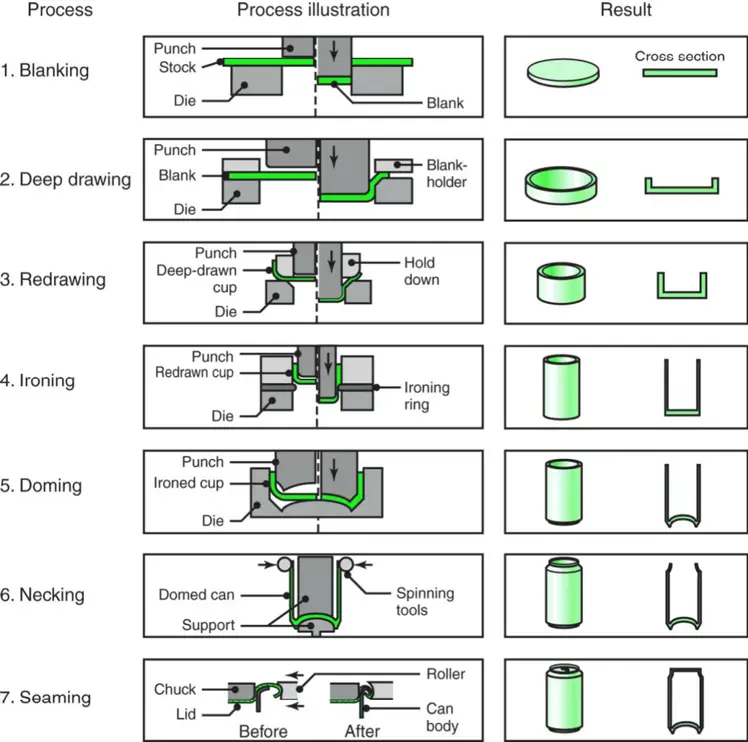

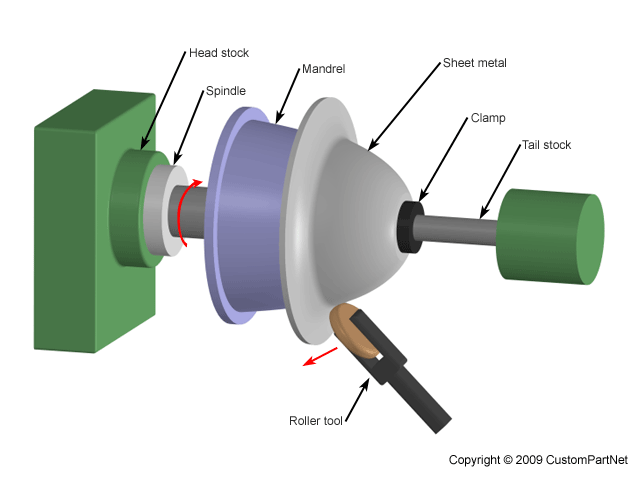

Progressive stamping uses one tool that performs multiple operations on one hit to make a complete part. These parts achieve their shape through the effects of the die tooling. The use of process control for sheet metal stamping greatly reduces defects in deep drawn parts and can also yield large material savings from reduced scrap. Stamping includes a variety of sheet metal forming manufacturing processes such as punching using a machine press or stamping press blanking embossing bending flanging and coining.

They are commonly developed using computer aided design cad software and analytical programs to create and prove out highly accurate unambiguous designs. Process control for sheet metal stamping presents a comprehensive and structured approach to the design and implementation of controllers for the sheet metal stamping process. Coining is a bending technique wherein the workpiece is stamped while placed between a die and the punch or press. Process control for sheet metal stamping allows the reader to design and implement process controllers in a typical manufacturing environment by retrofitting standard hydraulic or mechanical stamping presses and as such will be of interest to practising engineers working in metal working automotive and aeronautical industries.

Stamping dies are the tools that shape and cut sheet metal parts. Production stamping is generally performed on materials 020 to 080 thick but the process also can be applied to foils as thin as 001 or to plate. The use of process control for sheet metal stamping greatly reduces defects in deep drawn parts and can also yield large material savings from reduced scrap. The metal stamping process may involve one or more of the following actions.

Process control for sheet metal stamping presents a comprehensive and structured approach to the design and implementation of controllers for the sheet metal stamping process. Embossing is a process for creating either a raised or recessed design in sheet metal by pressing the raw blank against a die that contains the desired shape or by passing the material blank through a roller die.